Parts shortages, high gas prices weigh on US auto market

The automotive industry in the US may hit a recession at this rate.

-

The US automotive industry has been seeing a decrease in sales.

It is expected on Friday that major automakers will report that car and light truck sales in the US, in the first quarter of the year, are expected to have a sharp fall in comparison to sales a year ago, with some uncertainty coming through due to shortages in parts, increasing fuel prices and increasing interest rates.

J.D. Power and LMC Automotive predict that sales of cars and light trucks between January and March will decline 18% from a year ago, predicting that annualized sales for March will decline from 17.8 million to 12.7 million in comparison to a year ago.

Furthermore, Cox Automotive said earlier this week that the first quarter of US auto sales are the lowest in ten years.

Read more: Chip shortage forces Toyota to temporarily halt production

Tesla, however, might push back against the downward trend in sales. Wall Street predicts an improvement in Tesla sales from the fourth quarter figure of 308,650 vehicles. However, Elon Musk's company has had to shut down its factory in Shanghai to comply with COVID-19 lockdowns.

The US economy suffered setbacks since the beginning of the pandemic, and many automobile manufacturers have been seeking ways to find balance. However, the economy seems to drive further away from any sort of balance or security when gasoline crises have been on the rise due to the West-led war in Ukraine, in addition to the US' worst inflation in 40 years.

Increasing interest rates and gas prices, as per history, are signs of auto industry recessions.

On the other side, consumer intentions to buy vehicles, whether new or used, have decreased in March for the second month in a row. Intentions to buy used vehicles are at their lowest in 15 months, according to a Conference Board survey.

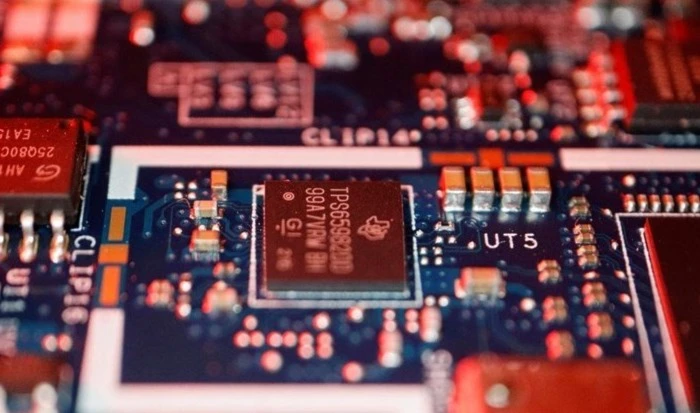

Microchip shortage causes $240 billion loss for US economy in 2021

According to analysts, a shortage of microchips in manufacturing processes in the US cost the US economy $240 billion last year, with electronics companies bearing the brunt of the impact.

According to CBS, disruptions were caused by the closure of key chip production sites in Asia owing to the epidemic.

The CEO of the Optimal Design company, Sajid Patel, told CBS on Friday that in some instances, production had to be scaled back because chips were unavailable, adding that "I think it's important for us to make this product in the United States. We're not making enough of it now. We have to make more of it. And the only way that you do that is to have more plants. And so this is the investment, frankly, in the future. It's not that far off."

The microchip scarcity has also hampered automobile production. Instead of driving immediately to the showroom, Ford vehicles were transported to parking lots from the assembly line where they waited for chips.

As a result, Ford lost $210 billion. The scarcity is predicted to worsen in the near future, but domestic chip manufacturing is expected to increase, with Intel announcing the development of a chip facility in the state of Ohio.

3 Min Read

3 Min Read